Contents

Micro hydro turbine generator hydro power stations debugging instruction-

Hydro power stations, also known as hydroelectric power stations or hydropower plants, are facilities that generate electricity from the kinetic energy of falling water. These facilities are typically located on rivers, streams, or other bodies of water with a sufficient flow rate and vertical drop to turn turbines and generate electricity.

The basic components of a hydro power station include:

- Dam or weir: A structure that creates a reservoir of water by impounding a river or stream.

- Intake structure: A structure that controls the flow of water into the power station, often equipped with screens or grates to prevent debris from entering the turbines.

- Penstock: A large pipe or conduit that carries the water from the intake to the turbines.

- Turbines: Mechanical devices that convert the kinetic energy of the falling water into rotational energy.

- Generators: Electrical machines that convert the rotational energy of the turbines into electrical energy.

- Transformer: A device that steps up the voltage of the electricity produced by the generators to a level suitable for transmission over long distances.

- Transmission lines: High voltage power lines that carry the electricity from the power station to the local distribution grid.

Hydro power stations can be classified into two main types: impoundment and run-of-river. Impoundment hydro power stations use a dam or weir to create a reservoir of water that can be stored and released as needed to generate electricity. Run-of-river hydro power stations do not have a reservoir and instead rely on the natural flow of the river or stream to turn the turbines.

Hydro power is a renewable and environmentally friendly source of energy, and hydro power stations can provide a reliable source of electricity to communities and industries around the world.

Line testing

The Line testing is mainly testing the power, testing whether there is a short circuit in the generator voltage three-phase, between the generator three-phase and network three-phase, or in the network three-phase, or between the generator three-phase and system power, or between the network three phases and system power, or among the system powers and testing every plug and every terminal block.

Preparation before “Start”

- Testing if the network has electricity, it can’t start to generate when the network is without electricity.

- Testing whether the governor is abnormal.

- Testing whether the guide vane or nozzle valve is fully closed, if not, please turns it off to the fully closed position.

- Testing whether the damper brake is resetting. If not, please reset it;

- Testing whether the circuit breaker is breaking. If it’s closing, let it break off. If it’s breaking, but the indicator light of the integrated automatic screen displays the closing status, please test whether the circuit breaker auxiliary contactor is bad or not.

- Turning on the valve;

- Turning on the generator cooling water system and bearing water cooling system.

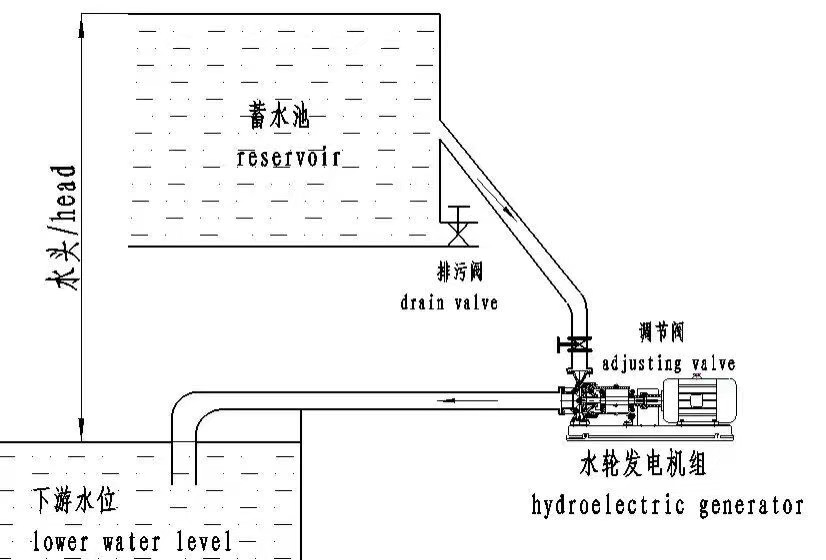

The construction of a micro hydro power stations- Find a good water resource

Micro water power generator system requires two basic elements:

one is water Flow (m3/s or liter/second);

two is to have a certain water Pressure (Mpa) (that is from the height of the water source to the downstream water tailrace, also known as Water Head). High water impulse in low water wheel and turns it, at the same time micro water turbine rotates and drives the generator, and you can get the electricity from your micro water power turbine generator.

Water flow: a good water source for a micro hydropower project should be a natural slope Steep River, streams, mountains creek, and mountain springs. And you have to know how much water flows in the dry season, and how much water flows in the flood season; all this is as the power of water consumption reference.

if you dong have any idea to measure the water flow of your micro water power generator project, check here “Measurement of water power generator project flow“to know.

Water head: with water and now to see the water Pressure Head, if there is a natural fall, it can save a lot of civil work and it will save your money, now you can build a water pool there as a good forebay, and then a water pressure pipe from the bay to your micro water power generator is an ideal design; If without a good natural waterfall, try to see if you can open a ditch along the hillside, to bring water to a downstream place to form a water pressure head, and build a water pool there as the forebay to store the water pressure.

if you dong have any idea to measure the water head of your micro water power generator project, check here “Measurement of water power generator project Head“to know.

Found the water, Form the water pressure head, Measure the water flow and head, Buy a micro water power turbine generator system, Build a powerhouse, and Install the micro hydro turbines machine, this is micro hydro stations.

The design and example of the micro hydropower reservoir/forebay

Some hydro power stations with a small flow but requirement of a high amount of electricity can adopt a reservoir for water shortage.

- Example(1): a mountain community/village with small water sources, minimum water flow is 2 kilograms per second during a year, and the head is 50 meters. There are 18 families in this village, designed electricity for every family is 150 watts (60 watts for the television, 90 watts for 4-5 light lamps), consider building a 3kw micro hydroelectric generator station. What is the solution for the forebay?

- Solution: For a 3kw pico hydro generator, 50 meters head, the client should choose a pico turgo turbine generator; the designed water flow should be 10 kilograms per second (10 liters/second). Because the existing water flow is too small (2 litter/s), building a reservoir can solve this problem. Calculate the daily water flow per hour (3600 x 2 = 7.2 cubic meters, 24 hours = 172.8 cubic meters.). About 180 cubic meters of water can be used to generate power. Power generation will consume 36 cubic meters of water (10 liters x 3600 seconds) per hour. Power 5 hours a day, low-flow water period can guarantee the villagers lighting electricity, flood season can get more power for another electricity usage.

Digging 180 cubic meters of water pool as the reservoir can power 5 hours per day. Good soil conditions can be connected with the tube directly; bad soil conditions of the pool can be used with plastic laying processing or concrete processing.

- Example (2) a hydropower station with drops 30 meters, dry season with 8.4 litter/second flow (30 cubic meters flow per hour), wet season with flow 41 litter/second (150 cubic meters per hour).

We can calculate the output of two flow conditions below:

Dry season output: 30 m ×0.0084(8.4 l/s) × 9.81×unit efficiency about 65% = 1606 watts

Wet season output: 30 m ×0.041(41 l/s) × 9.81×unit efficiency about 65% = 7843 watts

Requiring power is not less than 3000 watts; the designed flow is 16 liters per second. (30 m × 16 litter/seconds × 6 = 3060 watts)

- Solution: For the dry season, we need extra 8 kilograms per second water flow for the system, so we can get 8.4 litter+ 8 litters=16.4 litters water flow to meet the designed water flow condition, 3600 seconds * 8 = 28800 liters per hour (about 30 cubic meters) electricity 5 hours × 30 = 150 cubic meters.

This is a consideration design for the dry season, which is considered to build a 120-150 cubic reservoir, installed 6kw-8kw micro turgo turbine generator.

The client can get 3kw-4kw during the dry season, and get 6kw-8kw in the wet season. It is advisable to make an 8kw micro turgo turbine with two nozzles.

A 50 kW double nozzle hydro generator system typically refers to a hydroelectric power generation system that is capable of producing 50 kilowatts of electrical power using two nozzles. The system usually consists of a turbine, generator, control system, and other supporting equipment.

The basic working principle of a hydro generator system involves using the kinetic energy of flowing water to turn a turbine, which in turn drives a generator to produce electrical energy. The double nozzle system uses two nozzles to direct the water flow towards the turbine, which increases the efficiency of the system.

Such a system can be used to generate electricity in remote areas where other sources of power may not be available. It can also be used to supplement the power grid in areas where there is high demand for electricity.

Designing and installing a hydro generator system requires careful planning and engineering expertise to ensure that the system is efficient, reliable, and safe to operate. Factors such as the water flow rate, head pressure, turbine type, and generator capacity must be considered when designing such a system.

By Suneco Hydro

By Suneco Hydro