Contents

Micro hydro turbine generator installation acceptance requirements

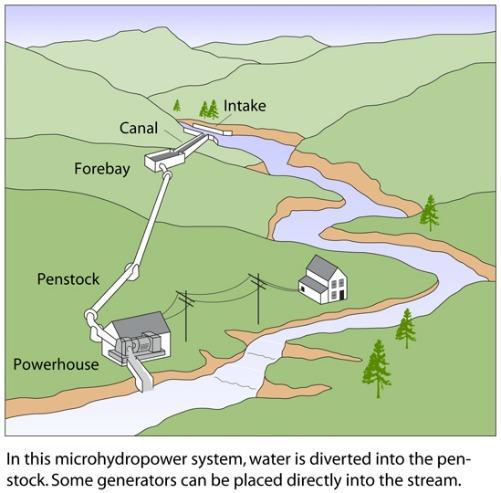

Civil works of micro hydro power generator project

Micro hydro project powerhouse parts

- The hydro turbine generator room should be set in a position without water immersion when a rising flood.

- Hydro turbine generator set installation should be firm and stable, powerhouse should be dry, with ventilation, and fluent drainage.

- Between the hydro turbine generator and pipeline connection, the place should be installed expansion joints for unit overhaul.

Micro hydro project Forebay pool

- Micro hydro project Forebay pool should be built in a safe location, the foundation is strong, and can’t build in the landslide area.

- Micro hydro project Forebay bottom should keep the sand flushing hole and the water inlet pipe should keep a 20cm distance from the bottom to be in order to prevent the sediment sand into the pipe and wearing the turbine.

- Inlet pipe setting depth should be immersed by water at least more than 50cm.

- Micro hydro project Forebay pool safety height should be higher than the highest water level of 30cm.

- Micro hydro project Forebay pool should have a spillway channel.

Micro hydro project Water channel section

- The water channel should guarantee that normal water passes to the forebay, and channel height should have a safety high of 10 ~ 20 cm from the water, in order to guarantee the flood season would not damage the channel by the flooding water.

- The channel slope ratio should be within 3/1000, and not wash the canal bottom too much to prevent mud sand sediment in the forebay.

The installation of the pressure pipe part

- The pipe should be selected in accordance with the micro hydro turbine manufacturer’s suggestion and rationally according to the hydraulic calculation method for the selection of hydraulic pipe diameter.

- Try to keep a straight pipe installation and try to reduce the bending; a straight pipe can reduce friction head loss more than a bent pipe.

- The length of more than 50 meters steel tube (the big temperature difference district figure is 30 meters) should install an expansion joint for connection.

- If using the plastic pipe as a pressure pipe installation, the plastic pipe should be buried underground to avoid ultraviolet radiation aging. The especially frozen region should be buried under the frozen soil layer.

- The connection between the pressure pipe and the powerhouse should set up a strong and reliable anchor block pier.

The telegraph pole part

- The electricity line pole construction must meet your local government’s electrical safety standards.

- Bare wire or exposed wire cannot be accepted for the micro hydropower project.

- The voltage drop between your micro hydro generator and the user power facility should be not greater than 10% (for 220v as a sample, not less than 200 volts).

- The pole transmission lines should be taken lightning protection measures; lightning arrester grounding must be good.

- The lines to every family should install electricity insurance and knife switch.

- The lamp holder, switch, and socket product is standard enough to ensure safety in power.

- The electricity line installation specification.

- The user should have electricity using safety knowledge for home

Designing and constructing a micro hydro power generator project requires careful planning and execution of civil works. Here are the steps to make civil works of a micro hydro power generator project:

- Site selection: Identify a suitable location for the micro hydro power generator project. The ideal site should have a steady and sufficient water supply, and the topography should have a sufficient head or drop to generate electricity.

- Water intake structure: Build a water intake structure that will direct the water to the turbine. The intake structure can be a concrete weir or a diversion canal that diverts water from a natural stream.

- Water conveyance system: Build a water conveyance system that will transport the water to the turbine. The conveyance system can be an open channel or a closed pipe system.

- Powerhouse: Construct a powerhouse to house the turbine and generator. The powerhouse can be built from concrete, brick, or stone, depending on the availability of materials in the area.

- Penstock: Install a penstock, which is a pipe that carries the water from the water conveyance system to the turbine. The penstock can be made of steel, concrete, or high-density polyethylene (HDPE).

- Turbine installation: Install the turbine and generator in the powerhouse. The turbine can be a Pelton, Francis, or Kaplan turbine, depending on the flow and head of the water.

- Electrical system: Install an electrical system to transmit the generated electricity to the grid or to the end-users. The electrical system should include a transformer, switchgear, and protective devices.

- Access road: Build an access road to the powerhouse to allow for maintenance and operation of the micro hydro power generator project.

- Environmental impact assessment: Conduct an environmental impact assessment to identify any potential impacts of the micro hydro power generator project on the environment and take measures to mitigate these impacts.

- Permitting: Obtain the necessary permits and approvals from the local authorities and regulatory bodies before commencing construction.

It is important to ensure that the civil works of the micro hydro power generator project are designed and constructed to meet safety, quality, and environmental standards. You may need to consult with an experienced civil engineer or contractor to ensure that the civil works are properly designed and executed.

By Suneco Hydro

By Suneco Hydro