The Francis turbine's adaptability extends to middle and low water heads and moderate to small flows, making it an ideal choice for hydropower stations.

In micro hydropower projects, particularly, the vertical type Francis turbine generator system is commonly employed.

This turbine, pivotal for harnessing energy from water, consists of key components such as the spiral case (water diversion chamber), turbine runner or wheel, water guide vane (wicket gates), and the draft tube.

Engineered to operate within water head ranges of 20-300 meters and with a specific suitable flow, the Francis turbine offers versatility in its applications.

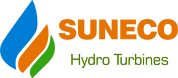

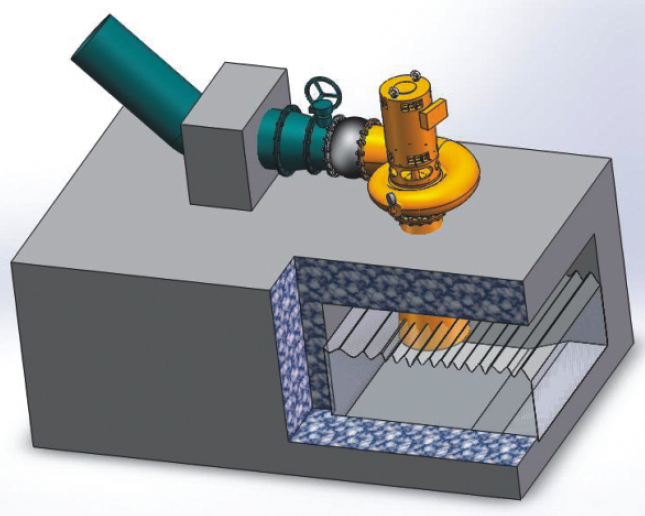

It can be configured in both vertical and horizontal arrangements. The vertical orientation is frequently favored for micro hydropower projects, providing compact and efficient solutions.

In the case of horizontal Francis turbine units, the design incorporates a horizontal shaft and can have 2 or 3 supports, usually arranged in a single stair configuration.

This arrangement ensures a simple structure, facilitating ease of operation and maintenance. The horizontal configuration's advantages lie in its straightforward design and accessibility, making it a practical choice for various hydropower applications.

Noteworthy is the Francis turbine's distinct advantages, including high efficiency, compact size, and a reliable structure.

These attributes make it a preferred choice for hydropower projects where optimizing energy conversion, space utilization, and structural dependability are paramount.

The horizontal arrangement, in particular, aligns with these advantages, offering a straightforward solution for harnessing hydroelectric power in diverse settings.

Francis turbine applies to middle and low water head and a middle and small flow of hydropower station.

Micro hydropower projects usually use vertical-type Francis turbine generator systems.

The turbine is mainly composed of spiral case (water diversion chamber), turbine runner or wheel, water guide vane (wicket gates), draft tube, etc.

Francis turbine is a kind of turbine suit to water head 20-300meters and with certain suitable flow.

It could be divided into vertical and horizontal arrangement.

Francis turbines have the advantage of high efficiency, small size, and reliable structure.

A horizontal Francis turbine unit, with a horizontal shaft, could have 2 or three supports.

Which is normally a stair arrangement. Simple structure, easier operation, and maintenance.