The weighted average efficiency is very high, and it has high efficiency in the whole operation range. In particular, the advanced Pelton turbine can achieve an average efficiency of more than 91% in the load range of 30% ~ 110%.

Suneco Hydro, a stalwart in hydroelectric solutions, redefines the industry with a holistic approach to excellence. Here's why choosing Suneco Hydro is a strategic decision for those seeking cutting-edge hydroelectric solutions.

7. Tailored Solutions at Negotiable Prices: Suneco Hydro prioritizes flexibility by offering negotiable prices. Recognizing the unique needs of clients, the company ensures that tailored hydroelectric solutions are accessible and cater to specific project budgets.

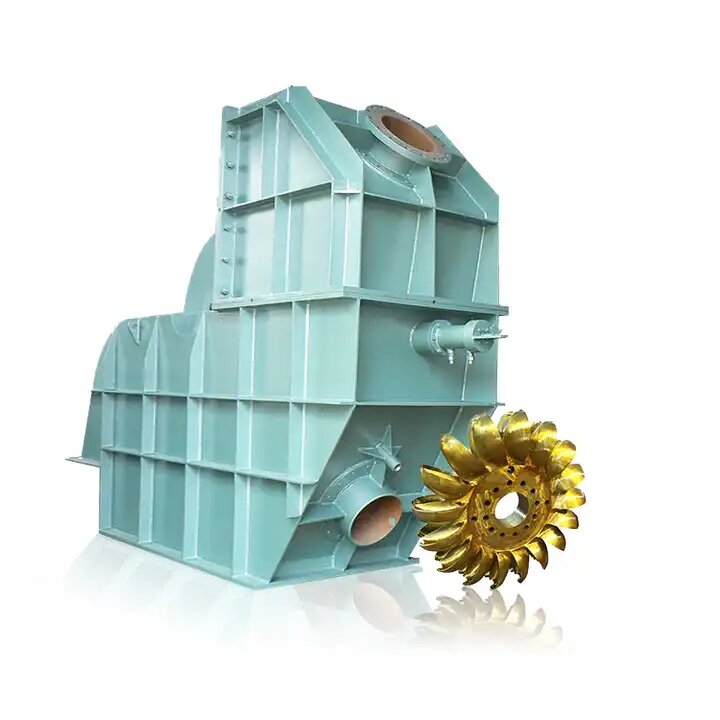

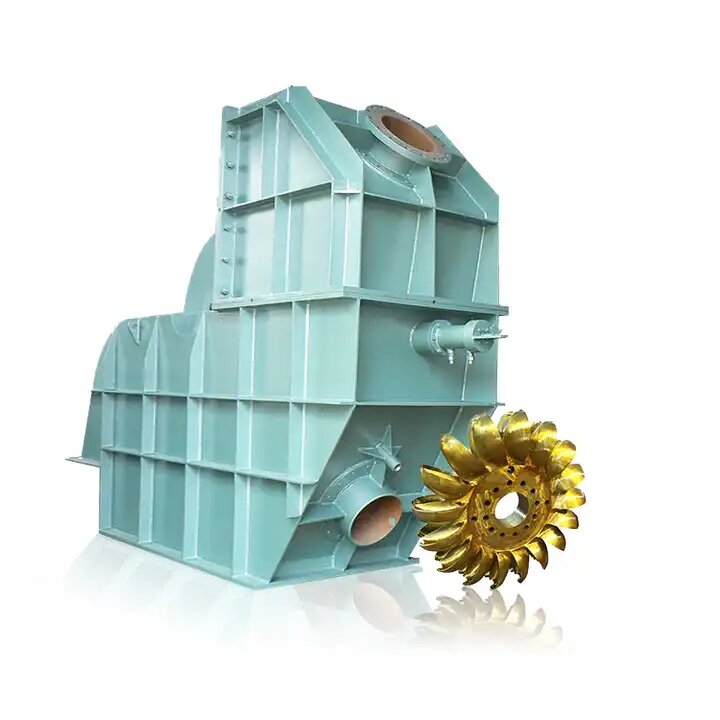

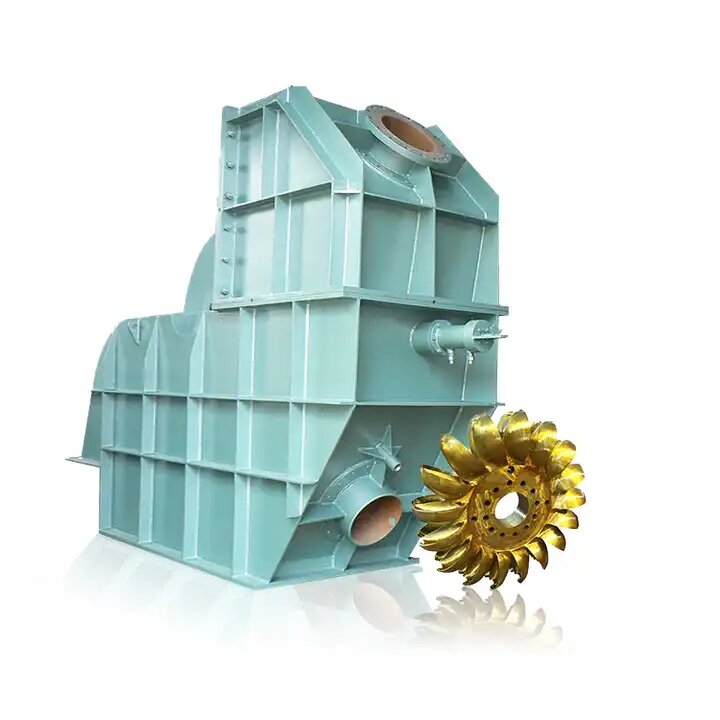

8. Demonstrating Impulse Turbine Expertise: The Pelton turbine, an impulse turbine type, is a hallmark of Suneco Hydro's expertise. Unlike reaction turbines, the Pelton turbine operates on the principle of water imparting impulse rather than a reactive force, showcasing Suneco Hydro's prowess in specialized turbine technologies.

9. Optimizing Hydroelectric Potential: Suneco Hydro maximizes hydroelectric potential by strategically placing water reservoirs above Pelton turbines. This design ensures a controlled flow through penstocks to specialized nozzles, delivering pressurized water to the turbines. The incorporation of surge tanks prevents pressure irregularities, guaranteeing consistent performance.

10. Realizing Efficiency in Upgrades: A testament to Suneco Hydro's commitment to efficiency is exemplified in the upgraded 2x200kW hydraulic station in China. Through meticulous replacement of hydraulic turbines, generators, and control systems, Suneco Hydro elevated the output power per unit from 150KW to an impressive 200kW. This success story reflects Suneco Hydro's capability to enhance existing hydroelectric infrastructure, optimizing performance and power output.

Suneco Hydro stands as an industry trailblazer, seamlessly integrating technological prowess, flexibility in pricing, impulse turbine expertise, and a track record of successful upgrades. Choosing Suneco Hydro is choosing progress, efficiency, and a reliable partner for innovative hydroelectric ventures.

Power: 200KW

Flow Rate: 0.25m³/s

Water Head: 103m

Price: Negotiable

Frequency: 50Hz/60Hz

Certificate: ISO9001/CE

Voltage: 400V

Efficiency: 93.5%

Generator Type: SFW200-12/850

Generator: Brushless Excitation Generator

Runner Material: Stainless Seel

Unlike other types of turbines which are reaction turbines, the Pelton turbine is known as an impulse turbine.

This simply means that instead of moving as a result of a reaction force, water creates some impulse on the turbine to get it to move.

When used for generating electricity, there is usually a water reservoir located at some height above the Pelton turbine.

The water then flows through the penstock to specialized nozzles that introduce pressurized water to the turbine.

To prevent irregularities in pressure, the penstock is fitted with a surge tank that absorbs sudden fluctuations in water that could alter the pressure.

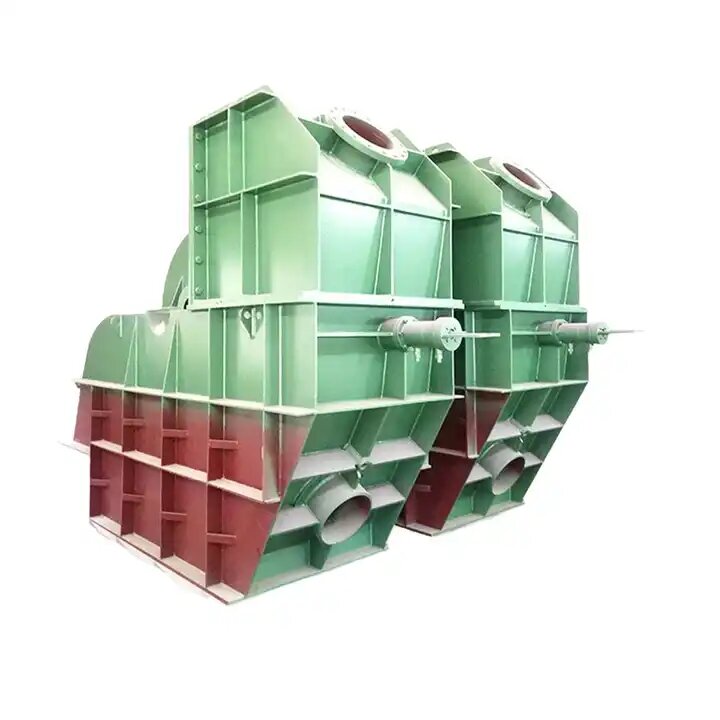

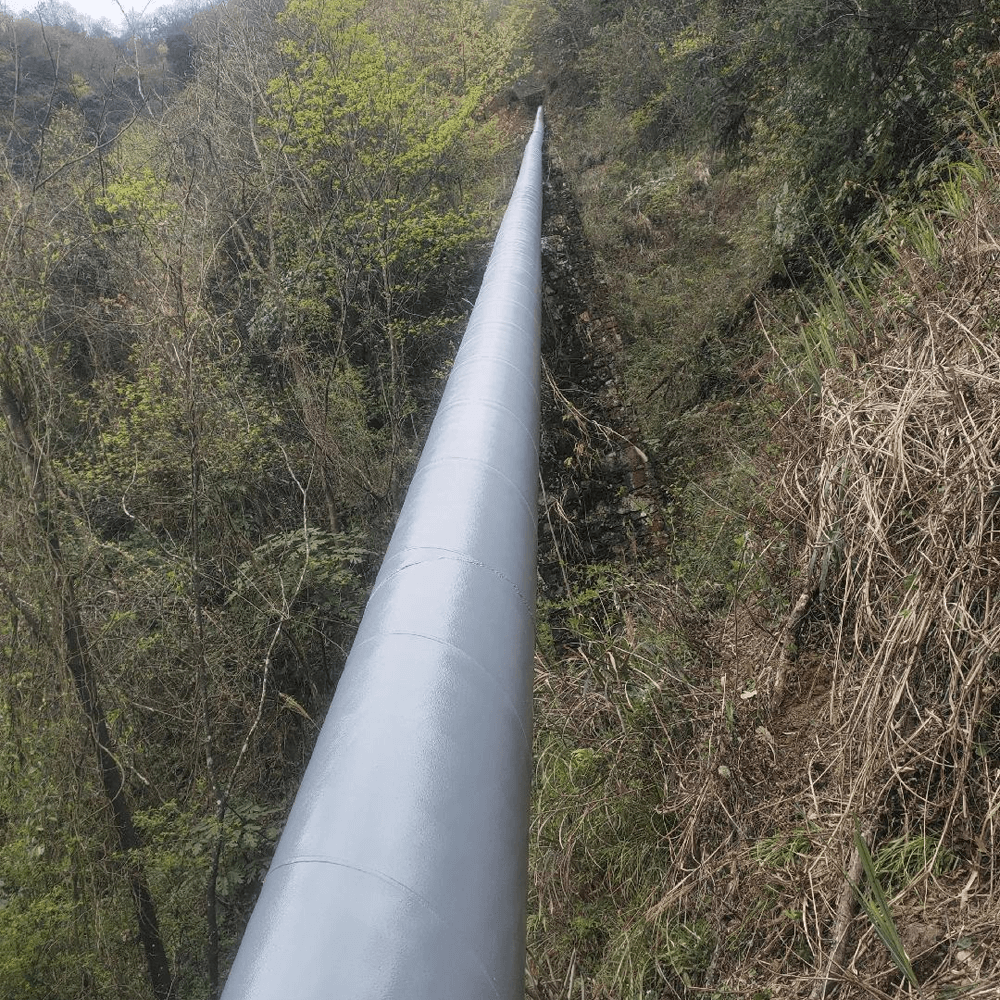

The following picture shows a 2x200kw hydraulic station upgraded by Suneco Hydro in China.

Suneco Hydro has replaced a brand-new hydraulic turbine, generator and control system, and the output power of a single unit has been increased from 150KW to 200kW.

The 2X200KW Pelton Hydraulic Electric Generator from Suneco Hydro exemplifies cutting-edge specifications tailored for optimal performance in hydroelectric applications. With a rated head of 103 meters and a flow rate of 0.25 m³/s, this powerhouse generator boasts an impressive efficiency rating of 93.5%, ensuring the effective conversion of water energy into electrical power.

Generating a total output of 2X200KW, the generator operates at a voltage of 400V and a current of 361A, with a frequency option of 50 or 60Hz. The rotary speed of 500 RPM ensures smooth and efficient operation. Designed for adaptability, the generator accommodates three phases, making it suitable for a range of hydroelectric projects.

The robust build of the generator is evident in its altitude tolerance of up to 3000 meters, with an IP44 protection grade ensuring resilience against environmental factors. Safety is a priority, with features like short circuit protection, insulation protection, and overload protection. The generator's connection method follows the straight league configuration.

For ease of transportation and protection, Suneco Hydro ensures that the generator is securely packed in a standard wooden box fixed with a steel frame. With these specifications, the 2X200KW Pelton Hydraulic Electric Generator stands as a testament to Suneco Hydro's commitment to delivering top-tier solutions for hydroelectric power generation.

| Rated Head | 103(meters) |

| Rated Flow | 0.25(m³/s) |

| Efficiency | 93.5(%) |

| Output | 2X200(KW) |

| Voltage | 400 (V) |

| Current | 361(A) |

| Frequency | 50 or 60(Hz) |

| Rotary Speed | 500(RPM) |

| Phase | Three(Phase) |

| Altitude | ≤3000(meters) |

| Protection Grade | IP44 |

| Temperature | -25~+50℃ |

| Relative Humidity | ≤90% |

| Connection Method | Straight League |

| Safety Protection | Short circuit Protection |

| Insulation Protection | |

| Over Load Protection | |

| Grounding Fault Protection | |

| Packing Material | Standard wooden box fixed with steel frame |

Adaptability to Flow and Head Ratio: Pelton Turbine Generators excel in situations with a relatively small ratio of flow to head, showcasing their versatility in diverse hydroelectric environments.

Exceptional Efficiency: Boasting a remarkably high weighted average efficiency, these generators consistently deliver superior performance across their entire operational spectrum. Advanced Pelton turbines, in particular, achieve an average efficiency exceeding 91% in the load range of 30% to 110%, ensuring optimal energy conversion.

Robust Head Change Adaptability: Pelton Turbines demonstrate robust adaptability to changes in head, making them suitable for varying hydrological conditions.

Suitability for Pipeline-to-Head Ratios: Particularly well-suited for locations with a large ratio of pipeline to head, Pelton Turbine Generators stand out as a practical choice for such scenarios.

Minimal Excavation Requirements: Pelton Turbine installations require a small amount of excavation, streamlining the construction process and reducing associated costs.

Utilizing Pelton turbines for power generation offers a broad output range, spanning from 50KW to 500MW. This flexibility accommodates a wide range of project sizes, especially in the high head range of 30m to 3000m. Notably, Pelton Turbine Generators eliminate the need for constructing dams and downstream draft tubes, resulting in a construction cost significantly lower than other water turbine generator units. This not only enhances cost-effectiveness but also minimizes the environmental impact, underscoring the eco-friendly attributes of Pelton Turbine Generator

Advantages of Pelton Turbine Generator

1. Adapt to the situation that the ratio of flow and head is relatively small.

2. The weighted average efficiency is very high, and it has high efficiency in the whole operation range. In particular, the advanced Pelton turbine can achieve an average efficiency of more than 91% in the load range of 30% ~ 110%.

3. Strong adaptability to head change

4. It is also very suitable for those with a large ratio of pipeline to head.

5. Small amount of excavation.

Using Pelton turbine for power generation, the output range can be from 50KW to 500MW, which can apply to the large head range of 30m to 3000m, especially in the high head range. Other types of turbines are not applicable, and there is no need to build dams and downstream draft tubes. The construction cost is only a fraction of that of other types of water turbine generator units, which has little impact on the natural environment.

Unlike other types of turbines which are reaction turbines, the Pelton turbine is known as an impulse turbine. This simply means that instead of moving as a result of a reaction force, water creates some impulse on the turbine to get it to move.

When used for generating electricity, there is usually a water reservoir located at some height above the Pelton turbine. The water then flows through the penstock to specialized nozzles that introduce pressurized water to the turbine. To prevent irregularities in pressure, the penstock is fitted with a surge tank that absorbs sudden fluctuations in water that could alter the pressure.